Products Details

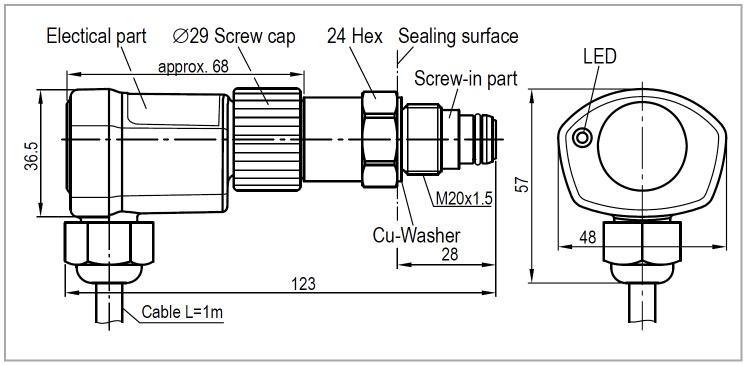

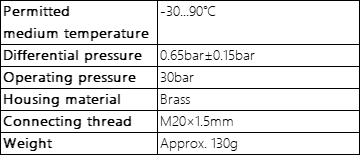

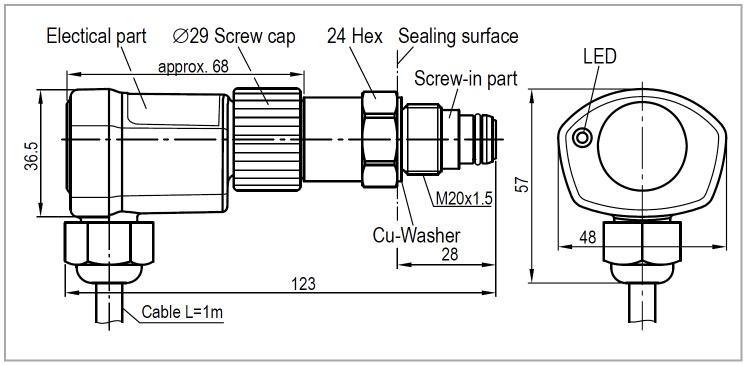

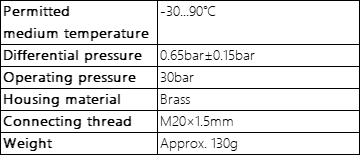

Delta pressure sensor servers to monitor the oil differential pressure of oil pumps in refrigeration compressors. For this a screw-in part that is mounted directly in the pump housing is evaluated for differential pressure measurement. The screw-in part is thereby connected by internal channels with the suction and high pressure side of the pump. Supplementary pipe connections are not needed. The evaluation unit is fastened by a coupling ring in the screw-in part and can be removed without opening the oil/refrigeration circuit. Once the supply voltage has been switched on, the relay trips after a 3 second delay time. With the operating recognition signal, which is applied to D1 of motor contactor (see wiring diagram), the differential pressure monitoring is activated after the expiration of a starting transition time. A missing differential pressure leads to a locked switch off after 90 seconds; with differential pressure fluctuation appropriately later (time integration).The monitoring of internal errors is always active. Any faults that occur in any operational phase lead to a locked switch off of the relay after 5 seconds. The potential-free, contact can be looped into a safety circuit without an auxiliary relay. An installation check monitors the proper assembly. The built-in LED indicates the operating state.

Delta pressure sensor servers to monitor the oil differential pressure of oil pumps in refrigeration compressors. For this a screw-in part that is mounted directly in the pump housing is evaluated for differential pressure measurement. The screw-in part is thereby connected by internal channels with the suction and high pressure side of the pump. Supplementary pipe connections are not needed. The evaluation unit is fastened by a coupling ring in the screw-in part and can be removed without opening the oil/refrigeration circuit. Once the supply voltage has been switched on, the relay trips after a 3 second delay time. With the operating recognition signal, which is applied to D1 of motor contactor (see wiring diagram), the differential pressure monitoring is activated after the expiration of a starting transition time. A missing differential pressure leads to a locked switch off after 90 seconds; with differential pressure fluctuation appropriately later (time integration).The monitoring of internal errors is always active. Any faults that occur in any operational phase lead to a locked switch off of the relay after 5 seconds. The potential-free, contact can be looped into a safety circuit without an auxiliary relay. An installation check monitors the proper assembly. The built-in LED indicates the operating state. Flash code of the red LED

10Hz flashing: internal error/voltage supply too low/Not screwed into screw-in part Continuous light: No differential pressure available Off: Differential pressure OK, no error

Carlyle Compressor,

Spring Feet,

Danfoss Lubricant Z,

Motor For Dorin,

Steel Gasket,

danfoss 160SZ,

"Industrial electrical box ",

Connecting Rod Of Dorin,

Electric Board For Refcomp Compressor,

Piston For Carrier,

Delta pressure sensor servers to monitor the oil differential pressure of oil pumps in refrigeration compressors. For this a screw-in part that is mounted directly in the pump housing is evaluated for differential pressure measurement. The screw-in part is thereby connected by internal channels with the suction and high pressure side of the pump. Supplementary pipe connections are not needed. The evaluation unit is fastened by a coupling ring in the screw-in part and can be removed without opening the oil/refrigeration circuit. Once the supply voltage has been switched on, the relay trips after a 3 second delay time. With the operating recognition signal, which is applied to D1 of motor contactor (see wiring diagram), the differential pressure monitoring is activated after the expiration of a starting transition time. A missing differential pressure leads to a locked switch off after 90 seconds; with differential pressure fluctuation appropriately later (time integration).The monitoring of internal errors is always active. Any faults that occur in any operational phase lead to a locked switch off of the relay after 5 seconds. The potential-free, contact can be looped into a safety circuit without an auxiliary relay. An installation check monitors the proper assembly. The built-in LED indicates the operating state.

Delta pressure sensor servers to monitor the oil differential pressure of oil pumps in refrigeration compressors. For this a screw-in part that is mounted directly in the pump housing is evaluated for differential pressure measurement. The screw-in part is thereby connected by internal channels with the suction and high pressure side of the pump. Supplementary pipe connections are not needed. The evaluation unit is fastened by a coupling ring in the screw-in part and can be removed without opening the oil/refrigeration circuit. Once the supply voltage has been switched on, the relay trips after a 3 second delay time. With the operating recognition signal, which is applied to D1 of motor contactor (see wiring diagram), the differential pressure monitoring is activated after the expiration of a starting transition time. A missing differential pressure leads to a locked switch off after 90 seconds; with differential pressure fluctuation appropriately later (time integration).The monitoring of internal errors is always active. Any faults that occur in any operational phase lead to a locked switch off of the relay after 5 seconds. The potential-free, contact can be looped into a safety circuit without an auxiliary relay. An installation check monitors the proper assembly. The built-in LED indicates the operating state.